Introduction

Walk through almost any older neighborhood in America and chances are you’ll spot a Craftsman style home. With its low, sloping roof, wide front porch, and earthy colors, the Craftsman has become one of the most beloved and recognizable American house styles.

But where did this style come from? Why did it become so popular in the early 20th century? And, as a paint company, we can’t ignore the obvious: what paint colors really bring out the best in a Craftsman home?

Let’s take a look at the history of the Craftsman style, how to identify one, and the timeless color palettes that make these homes come alive.

The Roots: Arts and Crafts in England

The story begins in England in the mid-1800s with the Arts and Crafts Movement. At the time, the Industrial Revolution was flooding homes with mass-produced goods. Furniture was heavily ornamented, machine-stamped, and often cheaply made to mimic luxury pieces.

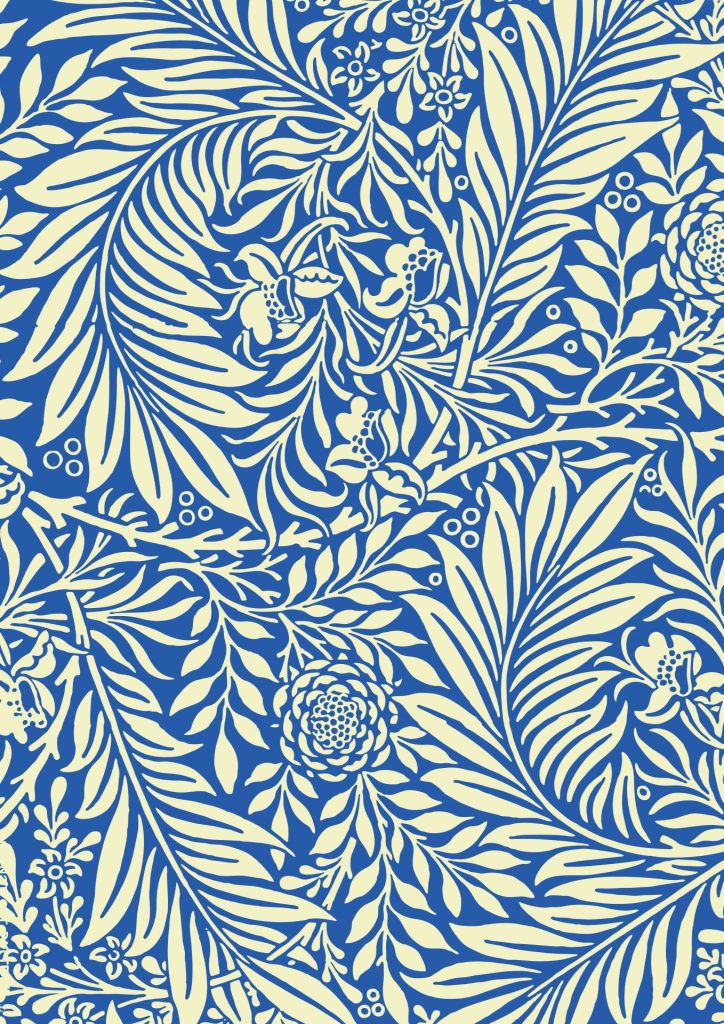

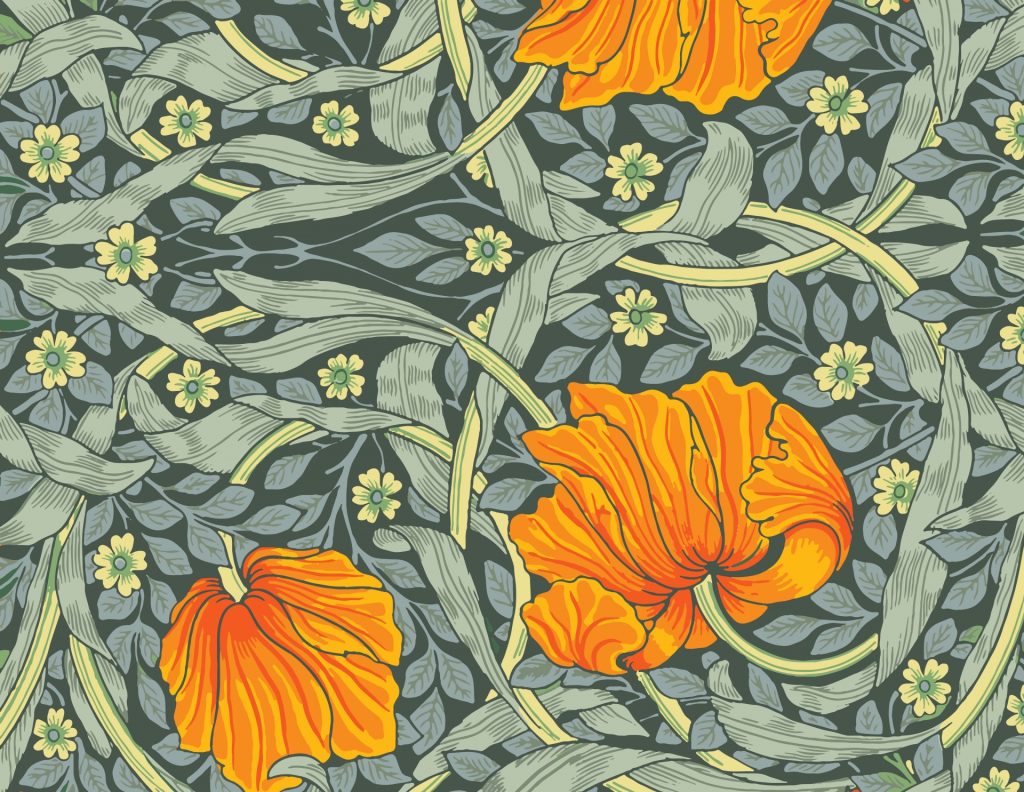

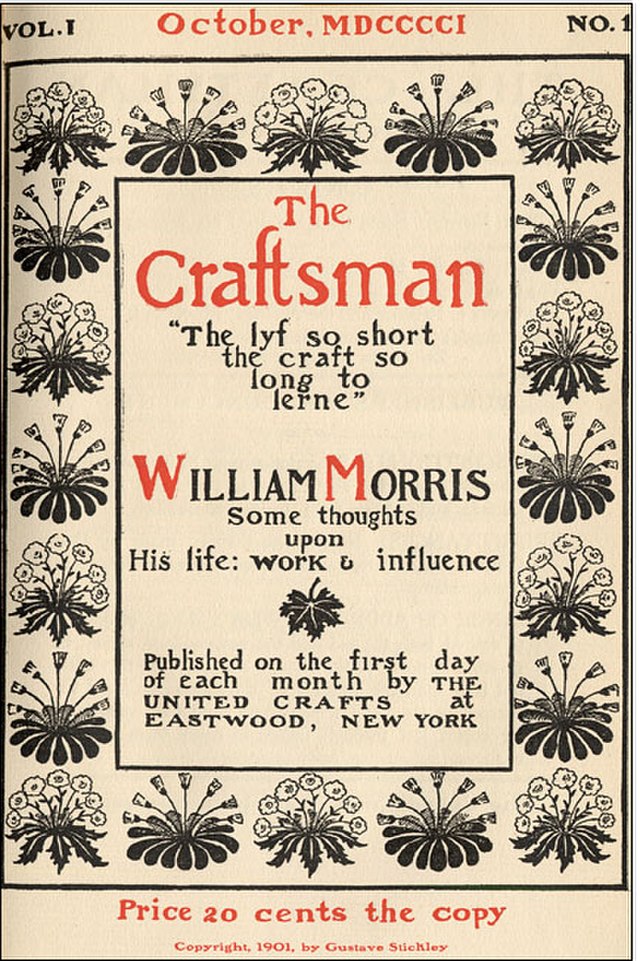

Not everyone loved that look. Designer William Morris and other reformers argued for a return to honest, handcrafted quality. They believed that the objects in our homes should be useful, beautiful, and connected to nature. Morris himself became famous for wallpaper and textile designs filled with flowing vines, flowers, and birds—patterns still made today.

By the late 19th century, the movement had crossed the Atlantic and was ready to reshape American homes.

The American Take: A Style for the People

In the United States, Arts and Crafts ideals evolved into what we call the Craftsman style.

Furniture maker Gustav Stickley helped popularize the look through his magazine The Craftsman (1901–1916), which featured not just furniture but also house plans that ordinary families could build.

At the same time, Sears, Roebuck & Co. began selling kit homes (1908–1942). These “Modern Homes” came in many styles—Colonial, Tudor, Four Square—but the bungalow form, often with Craftsman details, was especially popular. Kits arrived by railcar with precut lumber, nails, shingles, and everything needed to build the house.

And here’s a quick aside: Sears also sold Craftsman tools, starting in 1927. But the name is just a coincidence—the tool line had nothing to do with Craftsman homes. Still, it’s a quirky bit of history that Sears sold both Craftsman-style houses and Craftsman-brand wrenches in the same catalog!

The result was accessibility. Craftsman homes weren’t just for the wealthy; they were practical, affordable, and within reach for the growing middle class.

The Range: From Bungalows to “Ultimate Bungalows”

Most Craftsman homes were modest bungalows—one or one-and-a-half stories, simple, and practical.

But architects Charles and Henry Greene in Pasadena, California, elevated the style to high art with what became known as the “Ultimate Bungalows.” The most famous example is the Gamble House (1908), built for the Gamble family of Procter & Gamble. It’s filled with rich wood interiors, Japanese-inspired details, and custom furniture designed to match the architecture.

The Greenes also designed the Blackburn House, the Thorsen House, and others. Each blended architecture, furniture, and landscape into a seamless work of art.

So on one end of the spectrum you had the affordable Sears kit bungalow, and on the other, the Ultimate Bungalows—bespoke masterpieces for wealthy clients. Both fall under the Craftsman umbrella, which is part of the style’s richness.

Listen to Our Podcast on Craftsman Homes

How to Spot a Craftsman Style Home

A few telltale features help you recognize a Craftsman style home:

- Low-pitched gable roof with wide eaves

- Exposed rafters and decorative brackets

- Deep front porch supported by square or tapered columns on stone or brick bases

- Natural materials—wood, stone, brick, sometimes stucco

- Grouped windows, often double-hung with multiple panes on top

- Built-in features like bookcases, benches, or cabinets

- Central fireplace, usually stone or brick

- Earthy color palette—browns, greens, muted golds, and grays

Together, these features give Craftsman homes their warm, grounded feel.

Why the Craftsman Style Home Caught On

Craftsman homes became wildly popular between 1905 and the 1930s for three main reasons:

- Practicality: The bungalow was affordable, comfortable, and well-suited to the middle class.

- Philosophy: In an increasingly industrial and impersonal world, Craftsman homes represented authenticity, family, community, and a connection to nature.

- Beauty: Natural materials, earthy colors, and handcrafted details gave these homes a warmth that Victorian houses sometimes lacked.

Decline and Legacy

By the 1930s, Craftsman homes had begun to fade in popularity. The Great Depression slowed building, and new styles like Colonial Revival, Tudor, and Art Deco began to dominate.

But Craftsman homes never truly disappeared. Today, neighborhoods filled with these bungalows are among the most sought-after in America. Their scale, warmth, and timeless appeal continue to resonate, and their philosophy—simplicity, honesty, and connection to nature—feels just as relevant in our own industrial, digital age.

Paint Colors in the Craftsman Style Home

Now let’s talk about paint—because color is a big part of what makes Craftsman homes so distinctive.

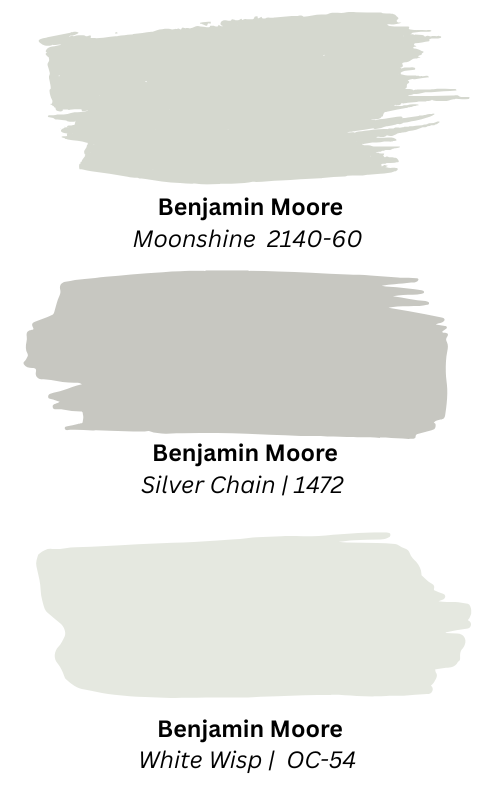

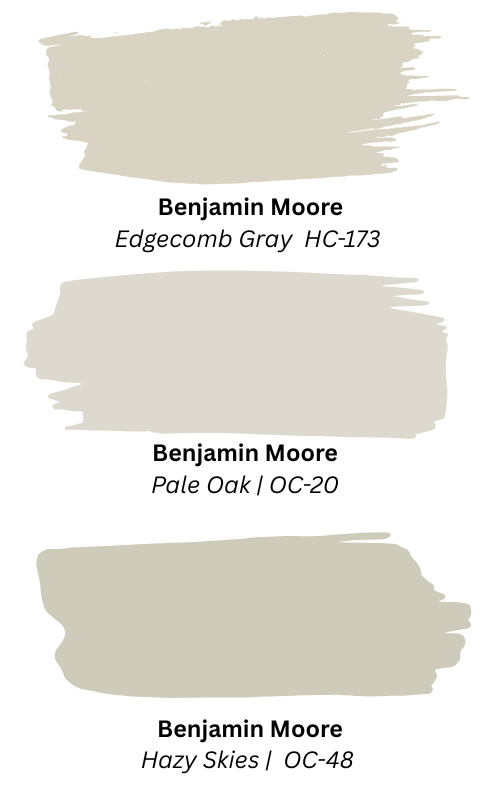

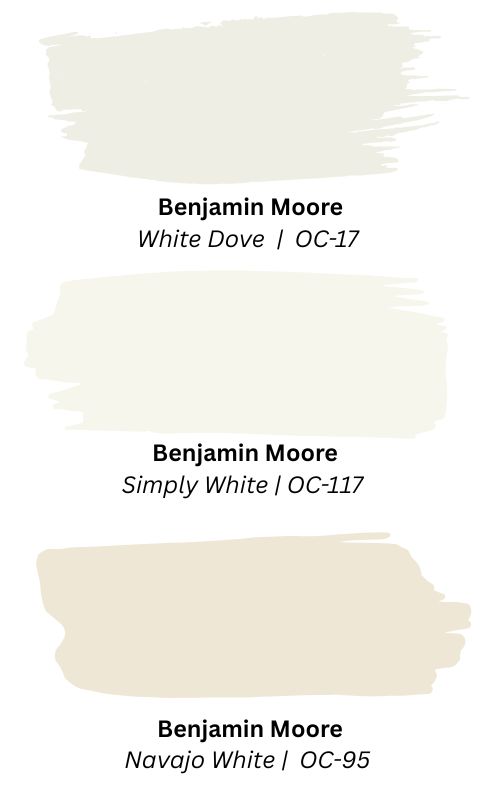

Traditionally, Craftsman homes were painted in earthy tones drawn from nature: greens, browns, russets, muted yellows, and soft grays. Trim often contrasted in a darker shade to highlight beams, brackets, and porch columns. Accent colors were used sparingly but dramatically on front doors or window sashes.

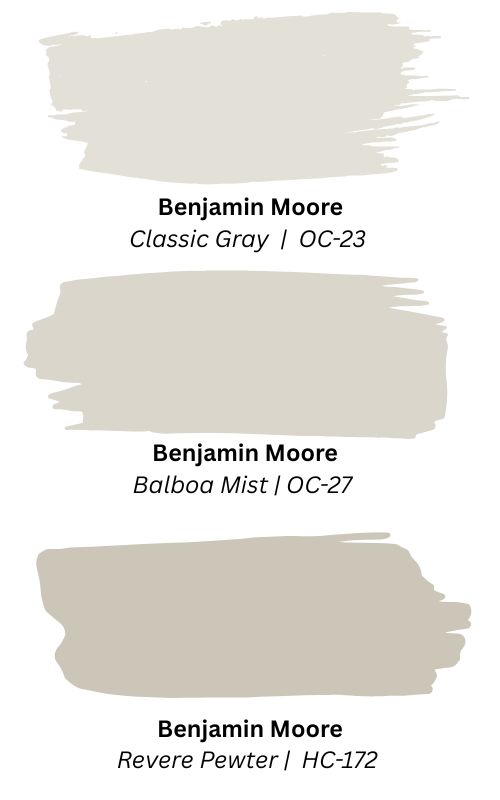

Here are some Benjamin Moore colors that echo the Craftsman palette:

Exteriors (body):

Trim:

Accents (doors, brackets):

Interiors:

Staying True—or Branching Out

Of course, color is always subjective. There’s no rule that says you must paint a Craftsman home in these shades. Bright whites, modern grays, or even unexpected pastels can work if handled thoughtfully. But here’s the challenge: choosing colors that fight against your home’s architecture can sometimes give you an uphill struggle. The space may never feel fully grounded or cohesive.

When you lean into your home’s architectural style—even loosely—you usually find the house feels “right.” Work against it, and sometimes the contrast sings… but other times, it just feels off.

That’s where we can help. At RepcoLite, our experts can guide you through choosing colors that not only look good on a chip but also make sense for your home’s design—whether you live in a Craftsman, Colonial, Ranch, or anything in between.

Conclusion

So the next time you walk down a street and see a house with a broad front porch, exposed rafters, and earthy colors, you’ll know you’re looking at a Craftsman style home. More than just architecture, it’s a piece of history—a design that spoke to America’s desire for authenticity, family, and a home that truly felt alive.